Hey there! 👋

Remember that time I tried cutting foam for a drone prototype with just a box cutter? Let’s just say it looked like a kindergartener’s art project gone wrong! 😂 That disaster led me down the rabbit hole of CNC-cut foam, and friends – it’s been a game-changer. Today, I’m sharing how this technology transforms ordinary foam into engineering masterpieces!

The Evolution of Foam Fabrication: From Scissors to Software

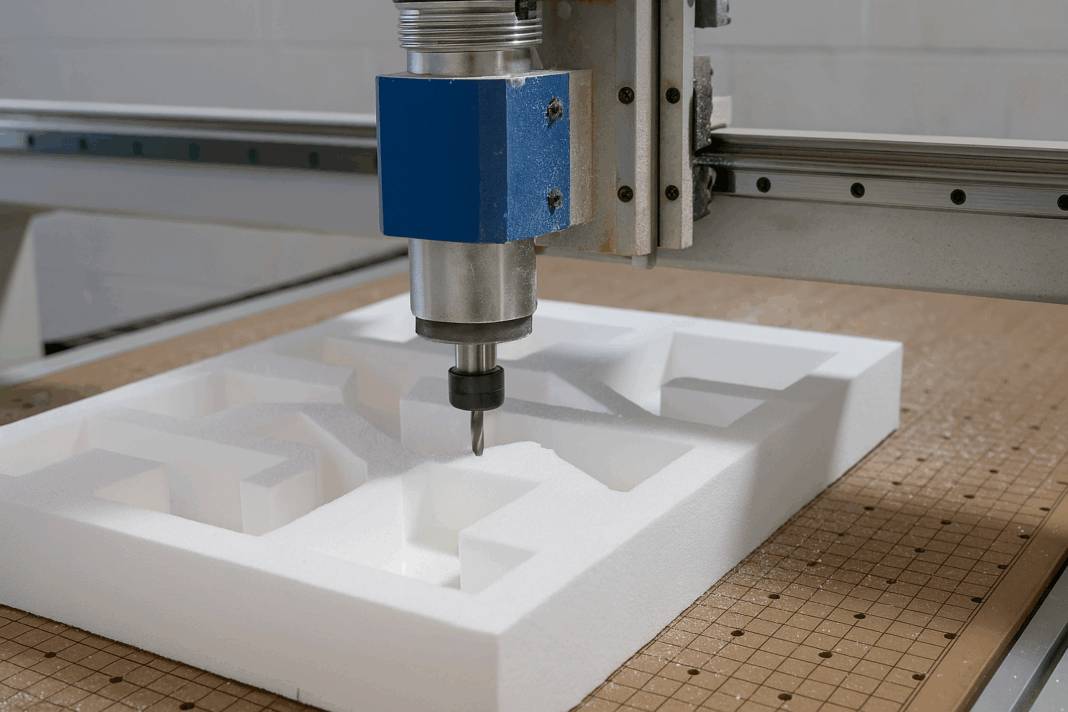

Traditional foam cutting reminds me of carving ice sculptures with a chainsaw – imprecise and messy. But CNC (Computer Numerical Control) cutting? That’s like giving foam a GPS-guided scalpel! 🗺️🔪 This technology uses CAD designs to guide ultra-sharp blades with micron-level precision.

I’ll never forget my first visit to a CNC foam facility. Watching that machine carve intricate patterns into polyethylene foam felt like witnessing magic. The operator grinned and said: “We make foam dance to the computer’s tune!” And honestly? He wasn’t wrong.

Why Precision Matters: The Cost of Imperfection

Early in my career, a client lost $40,000 in medical sensors because hand-cut foam inserts allowed movement during shipping. Each sensor needed 0.2mm precision – something only CNC could deliver. Here’s why accuracy isn’t just nice-to-have:

| Cutting Method | Tolerance Level | Waste Percentage | Complex Shape Capacity |

|---|---|---|---|

| Manual Cutting | ±3-5mm | 25-40% | Basic shapes only |

| Die Cutting | ±1-2mm | 15-25% | Moderate complexity |

| CNC Cutting | ±0.1-0.5mm | 3-8% | Any imaginable shape |

That medical client switched to CNC-cut physically cross linked polyethylene foam and eliminated shipping damage completely. Precision pays! 💰

The CNC Advantage: More Than Just Precision

Beyond accuracy, CNC cutting unlocks superpowers most people never consider:

- ✨ Multi-Layer Magic: Cutting 20+ identical layers simultaneously

- 🔄 Rapid Prototyping: Going from CAD design to physical part in hours

- 🎛️ Variable Density: Combining different foams in single structures

- 📐 Micro-Adjustments: Tweaking designs between batches digitally

My favorite example? An aerospace client needed shock-absorbing mounts with 57 unique angles. CNC delivered perfection where human hands couldn’t even measure accurately!

Material Matters: Foam Selection for CNC

Not all foams play nice with CNC blades! Through painful trial-and-error, I’ve learned:

Closed-Cell Champions: Chemically cross linked polyethylene foam cuts cleaner than warm butter 🧈, leaving smooth edges that won’t crumble.

Avoid Open-Cell Nightmares: Standard polyurethane foam often tears like tissue paper, requiring messy secondary processing.

Density Sweet Spot: 30-60 kg/m³ pe foam offers the perfect balance of cut precision and structural integrity.

Mind-Blowing Applications: Where CNC Foam Shines

The possibilities make my inner engineer giddy! Here’s what clients are creating:

Biomedical Marvels: Custom surgical trays with instrument-specific cavities cut to 0.1mm tolerance.

Acoustic Sculptures: Sound-diffusing panels with mathematically precise fractal patterns.

Transport Revolution: Vehicle interiors with ergonomic contours following body mechanics.

I recently saw CNC-cut foam mimicking coral reefs for aquarium habitats – the sea turtles approved! 🐢❤️

The Cost Paradox: Why CNC Saves Money

Many clients panic at CNC’s hourly rate. But consider:

- 📉 Reduced Waste: Nesting software fits pieces like a puzzle, minimizing material use

- ⏱️ Zero Setup Costs: Change designs without physical tool modifications

- 🔄 Consistency: The 1000th cut matches the 1st perfectly

A furniture client discovered CNC-cut foam reduced their assembly time by 65% because pieces fit perfectly every time. That’s efficiency you can’t buy with cheap labor!

Designing for CNC: Insider Tips

After overseeing 500+ CNC projects, here’s my cheat sheet:

- Mind the Kerf: 🔪 Blades remove 0.5-2mm material – account for this in designs!

- Internal Corners: Add tiny radii (0.5mm) to prevent tearing

- Layer Orientation: Cutting perpendicular to foam rise direction yields cleaner edges

- Test Cuts: Always prototype with scrap material first

Future Frontiers: Where CNC Foam is Heading

The technology advancing faster than ever:

AI-Optimized Cutting Paths: 🤖 Software that learns to minimize cutting time and waste

3D Foam Printing: Layering CNC-cut sheets into complex 3D structures

Hybrid Material Systems: Embedding sensors or reinforcing fibers during cutting

I recently witnessed a CNC machine cutting conductive foam circuits – the future is flexible! 🔌

Your CNC Journey Starts Here

Ready to embrace precision foam cutting? My battle-tested roadmap:

- Start Simple: Choose one high-impact component to CNC first

- Partner Early: Engage CNC experts during design phase

- Material Testing: Verify your foam cuts cleanly before full production

That botched drone prototype taught me a valuable lesson: In foam cutting, precision isn’t luxury – it’s necessity. ✨ Whether you’re protecting delicate electronics or creating artistic installations, CNC turns “good enough” into “perfect every time.” Now go blow some minds with foam! 💥🧠

You should also read these…

- noepic.com – troubleshooting with twitter x search operators a

- godwig.com – tiktok live eligibility requirements and common is

- huesly.com – transforming industrial spaces with smart storage

- toojet.com – instagram location and map strategy for businesses

- spyfrogs.com – industrial packaging with durfoam protecting goods

- tugmen.com – the role of foam in modern packaging solutions

- toojet.com – twitter x embed api changes version migration and

- closedad.com – how rd drives performance improvements in industri

- surgeblog.com – the physics of heat transfer insulation materials

- godwig.com – fortnite fps drops performance settings guide